Forum Migration Notice

We're transitioning to a more modern community platform by beginning of next year. Learn about the upcoming changes and what to expect.

Simulate a punctual force to calculate Payload from a Jet lance tool

eKoh

✭

in RobotStudio

Hello guys! I am in a hurry. Can you guys help me please?

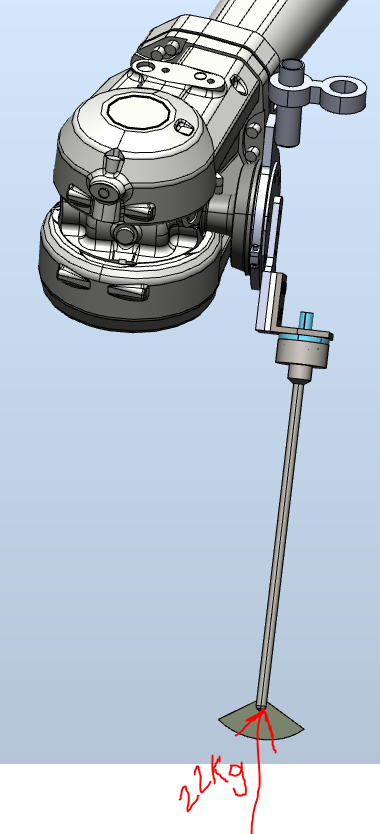

I need to simulate a punctual force of 22Kg in opposite direction from the jet, for a jet lance tool. As explained in the following picture:

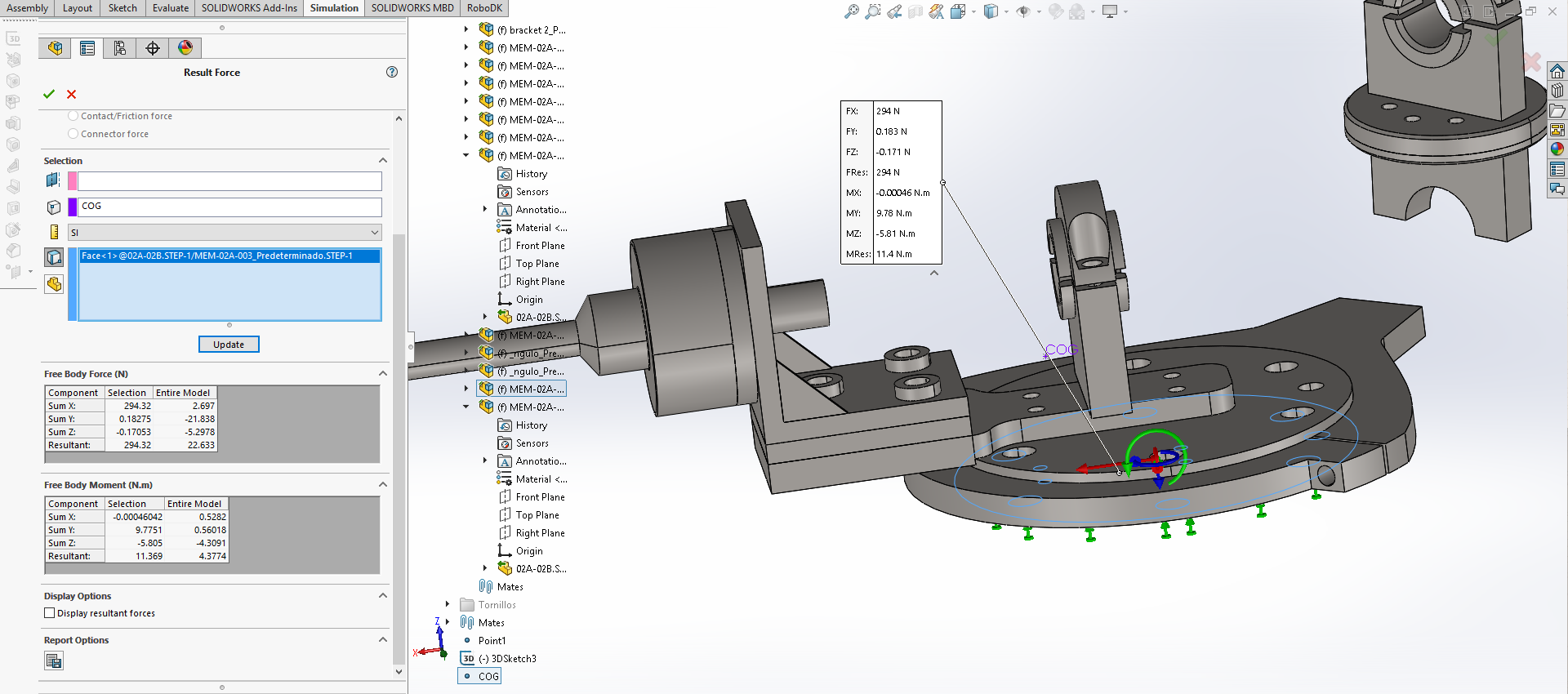

I tried doing this in Solidworks, by applying this force on a Static simulation and focusing on the COG by reading the Result forces given on that point and the flange. As it shows the following picture:

This study was done with 30kg, so 294N in force with

COG x:29.94 y=-16.96 z=31.49

Also, the mass of the study is the same from the real tool.

Given the MX, MY, MZ, I assume those are the moments of inertia and I just converted the N*m to Kg*m for the payload results which are these:

I need to simulate a punctual force of 22Kg in opposite direction from the jet, for a jet lance tool. As explained in the following picture:

I tried doing this in Solidworks, by applying this force on a Static simulation and focusing on the COG by reading the Result forces given on that point and the flange. As it shows the following picture:

This study was done with 30kg, so 294N in force with

COG x:29.94 y=-16.96 z=31.49

Also, the mass of the study is the same from the real tool.

Given the MX, MY, MZ, I assume those are the moments of inertia and I just converted the N*m to Kg*m for the payload results which are these:

Ix 0.000

Iy 0.9973

Iz -0.5925

So I applied this inertia to the payload.

But I am not sure if I am right, it's the first time I do this and wondering if it is all done right.

The thing that bothers me is that the moments of inertia the unit is Kg*m^2 and the MX, MY, MZ values from the picture are N*m given that N=Kg*m /s^2, if I apply that then the result unit would be:

Kg*m^2/s^2

I still have that s^2, not sure what about this. Btw, I am an electronic engineer, I dont have a lot of knowledge from this stuff. But I always do my best:)

Thanks in advance, I hope you all have a good day!

So I applied this inertia to the payload.

But I am not sure if I am right, it's the first time I do this and wondering if it is all done right.

The thing that bothers me is that the moments of inertia the unit is Kg*m^2 and the MX, MY, MZ values from the picture are N*m given that N=Kg*m /s^2, if I apply that then the result unit would be:

Kg*m^2/s^2

I still have that s^2, not sure what about this. Btw, I am an electronic engineer, I dont have a lot of knowledge from this stuff. But I always do my best:)

Thanks in advance, I hope you all have a good day!

0

Comments

-

UPDATE:

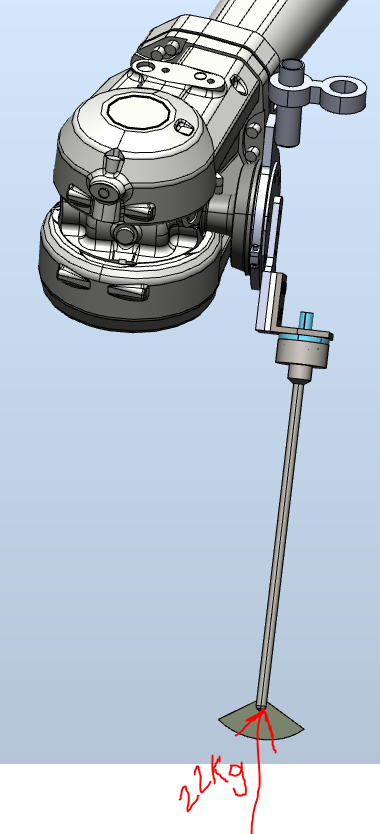

Hello guys, I've just ran a 22kg force simulation. And approached from a different face rather than the tool flange.

So first of all, that's the force that I am applying.

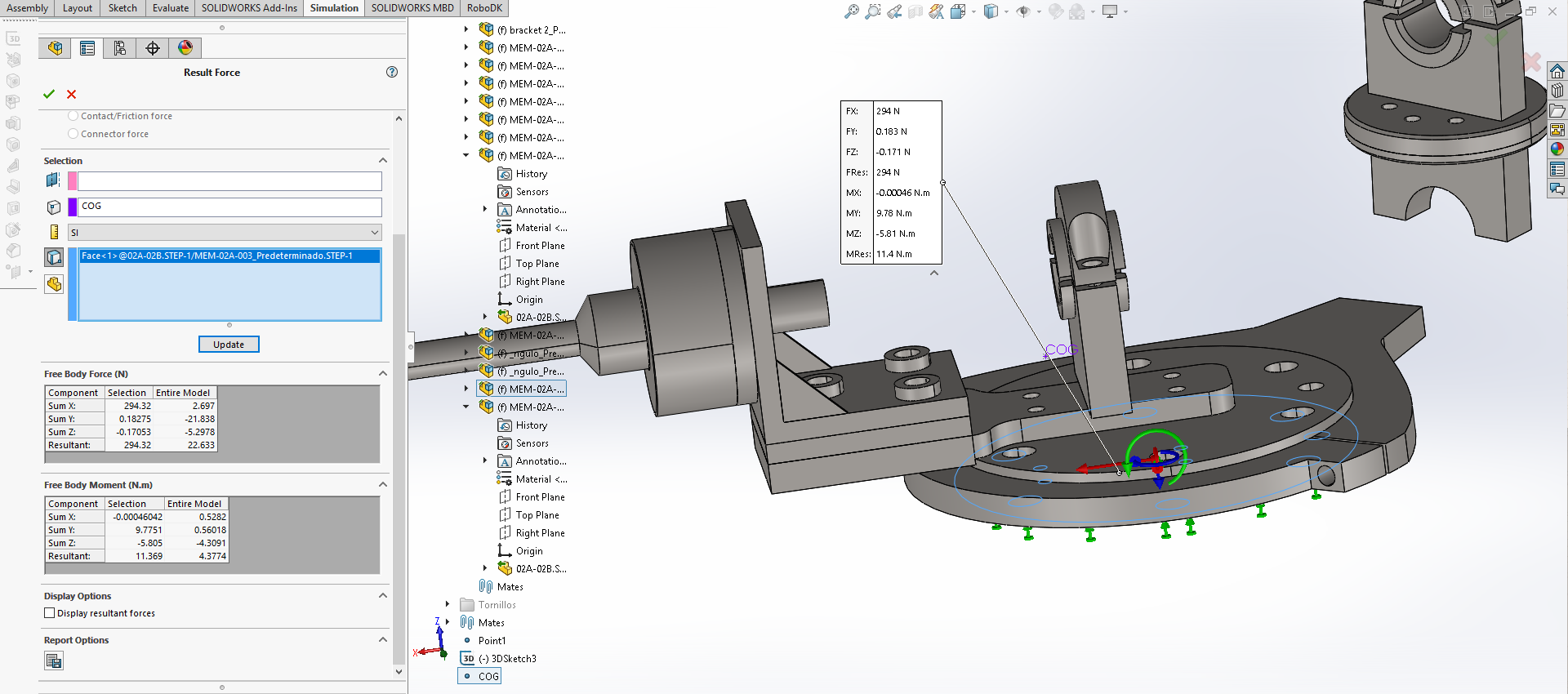

And this is the result:

So, I can tell Mx, My and Mz, are Ix, Iy, Iz from loaddata value from tooldata.Payload with 22Kg punctual forceMass 4.882kgCOG x:28.46 y=-19.72 z=31.41 [mm]Ix 0.000Iy -0.731Iz 0.434 [kgm]loaddata format from Robotstudio[4.882,[28.46,-19.72,31.41],[1,0,0,0],0,-0.731,0.434]]

I think this is a fairly good result, I guess. Am not 100% sure, I have very little knowledge on doing this~~

Thank you in advance 0

0 -

If you are trying to calculate the values to use for the loaddata - would the mass not be 22 kg with the cog being the end of the lance (it is pretty much a point load)?

The mass and inertia of the lance and bracket are entered as the tooldata.

0 -

My Idea would be to call the LoadIdentify Routine at the real robot with the jet turned on, if that would be possible.

1 -

Indeed, we had to do that. From loadidentify the loaddata = 26.81,[466.12,-2.83,56.82]EricH said:My Idea would be to call the LoadIdentify Routine at the real robot with the jet turned on, if that would be possible.

Mass = 26.81kg

Ix = 466.12

Iy = -2.383

Iz = 56.82

Way different from simulation. I was asked for this task, so there wouldn't be a mess in plant. But sometimes it's easier to clean a mess than break your head for something likely impossible.0 -

You keep saying Loaddata, but as Graeme pointed out, you should have the payload for the tool itself in the tooldata. Loaddata is in tool coordinates. Also, did you ensure that you have done ALL of the prerequisites for doing a proper loadidentify? Any mounted armloads entered, calibrated TCP...all the prompts that loadidentify asks when you start running it?Lee Justice0

-

I keep saying Loaddata because it is a variable within Tooldata, and I am only focusing on that since it is the relevant information I need. As shown in the picture taken from RAPID:lemster68 said:You keep saying Loaddata, but as Graeme pointed out, you should have the payload for the tool itself in the tooldata. Loaddata is in tool coordinates. Also, did you ensure that you have done ALL of the prerequisites for doing a proper loadidentify? Any mounted armloads entered, calibrated TCP...all the prompts that loadidentify asks when you start running it?

And I can tell the loadidentify routine was run correctly.0 -

The values you calculated are torque and you have to convert them to moment of inertia: http://www.softschools.com/formulas/physics/torque_formula/59/

0 -

Oh thank you so much. I have very little knowledge on this stuff, so glad to see somebody correcting meEricH said:The values you calculated are torque and you have to convert them to moment of inertia: http://www.softschools.com/formulas/physics/torque_formula/59/

0

Categories

- All Categories

- 5.7K RobotStudio

- 401 UpFeed

- 21 Tutorials

- 16 RobotApps

- 306 PowerPacs

- 407 RobotStudio S4

- 1.8K Developer Tools

- 251 ScreenMaker

- 2.9K Robot Controller

- 367 IRC5

- 91 OmniCore

- 8 RCS (Realistic Controller Simulation)

- 858 RAPID Programming

- 43 AppStudio

- 4 RobotStudio AR Viewer

- 19 Wizard Easy Programming

- 111 Collaborative Robots

- 5 Job listings