Forum Migration Notice

Update (2026-01-21): The user forums are now in read-only mode pending the data migration.

Update (2026-01-12): The user forums will be put into read-only mode on the 21st of January, 00:00 CET, to prepare for the data migration.

We're transitioning to a more modern community platform by beginning of next year. Learn about the upcoming changes and what to expect.

Update (2026-01-12): The user forums will be put into read-only mode on the 21st of January, 00:00 CET, to prepare for the data migration.

We're transitioning to a more modern community platform by beginning of next year. Learn about the upcoming changes and what to expect.

How to configure a second EtherNet/IP network and connection

Jaycephus

✭✭

I have a scanner and adapter preconfigured on an IRC 5 with CIP Safety.

The scanner side connects (factory configured) to ABB DIO module.

I modified the cable routing to put this IO module on the included switch, so that two other adapter devices could be put on the same switch and connect to the scanner.

The adapter side of the default EIP network is factory configured with CIP Safety.

My issue is that I need another adapter to communicate with an A-B PLC.

The scanner side connects (factory configured) to ABB DIO module.

I modified the cable routing to put this IO module on the included switch, so that two other adapter devices could be put on the same switch and connect to the scanner.

The adapter side of the default EIP network is factory configured with CIP Safety.

My issue is that I need another adapter to communicate with an A-B PLC.

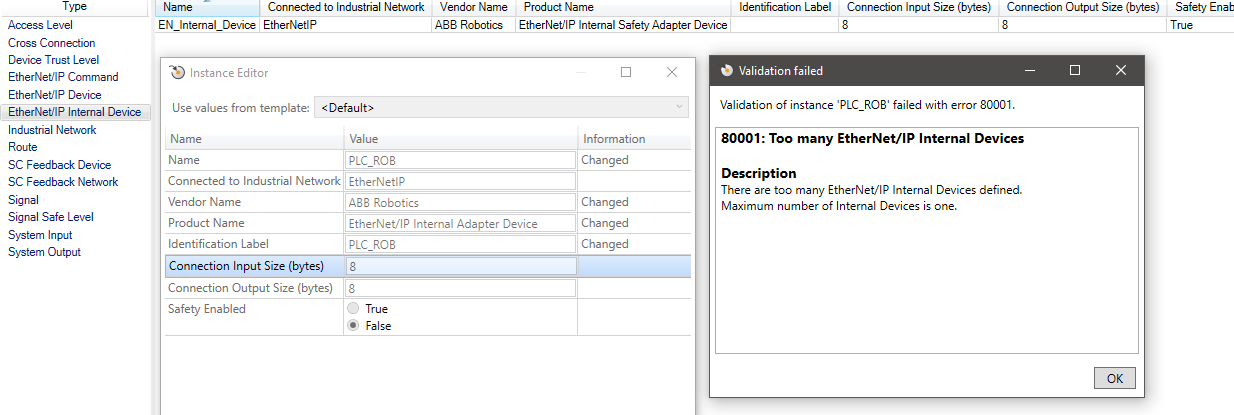

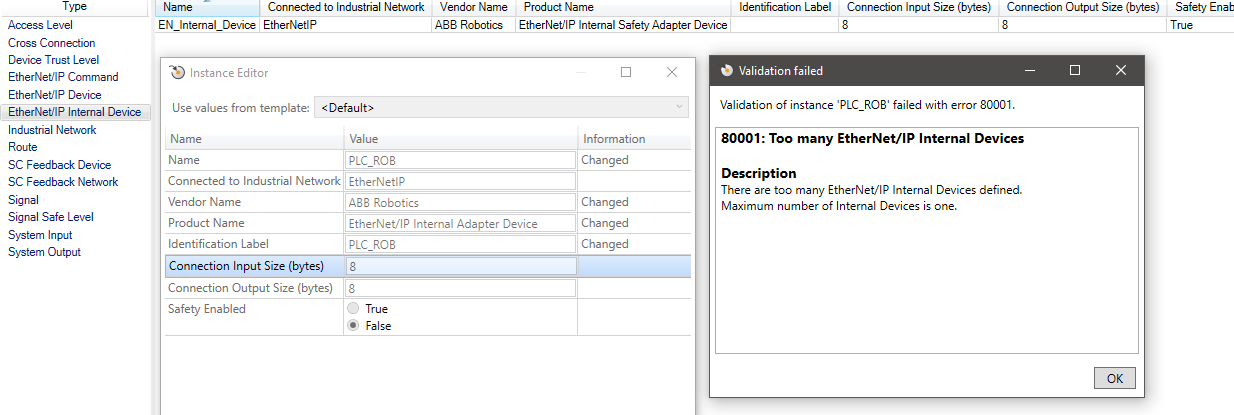

If trying to configure another EIP Adapter, I get the Error that only one is allowed:

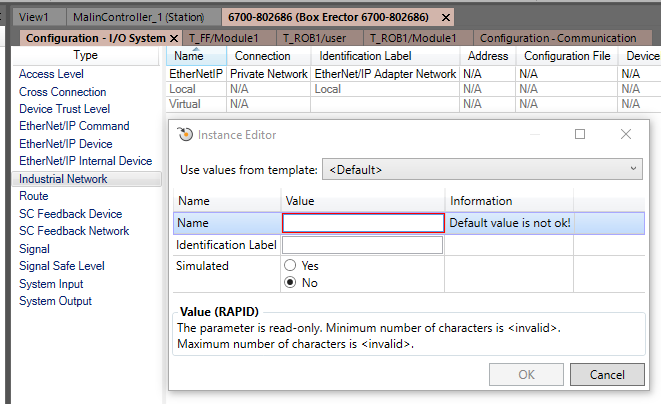

This is because the only allowed Industrial Network is EtherNetIP, and that field is read-only.

The EtherNet/IP ABB manual really does not go into this detail.

I'm assuming that I need to create a second Industrial Network, because there can only be one ABB controller adapter per network.

And if so...

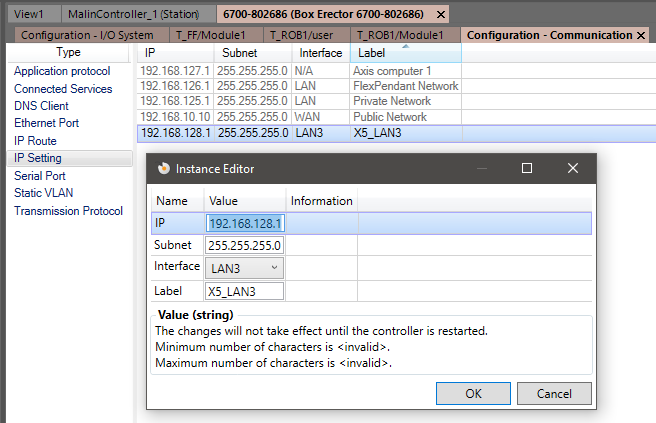

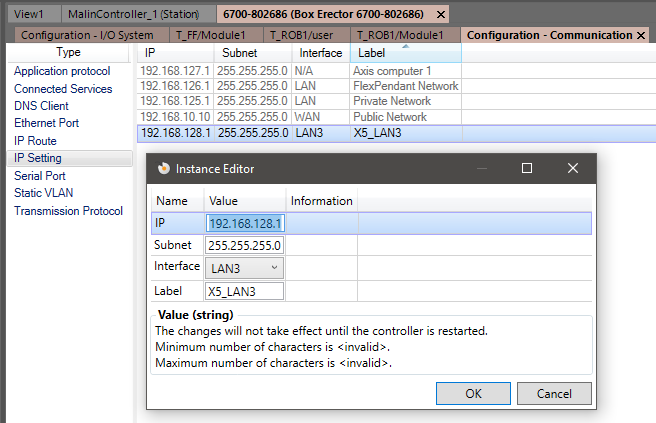

I can create a network using LAN3:

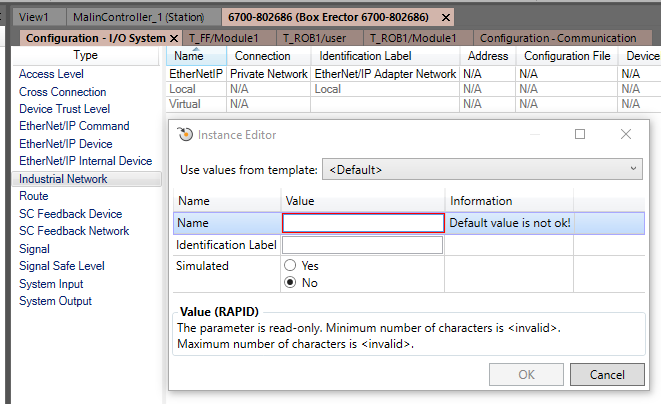

But it won't let me create another industrial network:

The Name field is read-only and cannot be changed.

Thanks,

Jay

This is because the only allowed Industrial Network is EtherNetIP, and that field is read-only.

The EtherNet/IP ABB manual really does not go into this detail.

I'm assuming that I need to create a second Industrial Network, because there can only be one ABB controller adapter per network.

And if so...

I can create a network using LAN3:

But it won't let me create another industrial network:

The Name field is read-only and cannot be changed.

Thanks,

Jay

- Jay

0

Best Answers

-

I think you need purchase the EthernetIP Fieldbus adapter (option 840-1).

This allows you to have a completely separate connection.0 -

One potentially cheaper and more 'ideal' answer is that the pre-configured CIP Safety adapter can be edited to act as both the CIP Safety I/O, and any additional process I/O that you need.

The CIP Safety adapter is pre-configured to 8 bytes IN and 8 bytes OUT, but can be reconfigured with more bytes for additional non-safe I/O.

Just don't mess with the first 8 bytes of the inputs and outputs. The PLC side just needs to match whatever process I/O structure you have appended to it on the Robot side.

In my case I need 3 extra bytes for Inputs and 11 bytes for outputs.

The manual is just silent on that, I think. I assumed that the 8 IN/OUT bytes were fixed, and if using CIP safety, the pre-configured adapter shouldn't be tampered with, since it's 'Safety' related.- Jay0 -

No...graemepaulin said:Could this... or this be the issue (FBA = (Anybus) fieldbus adapter)

Basically, the 841-1 EtherNet/IP adapter/Scanner (s/M) option was perfect for our needs, until a contractor on this project requested the addition of CIP Safety (in order to avoid hardwiring the safety controls to four different robots cells). This confused the issue for me, since I've never used CIP Safety before, and wasn't familiar with the factory configuration.

The robot came preconfigured with both. What was unclear in the Application Manual for EtherNet/IP 841-1 was that CIP Safety must be combined with 841-1, not 840-1 (EtherNet/IP Field Bus Adapter). This is according to an ABB engineer. If I recall correctly, it's also not made clear that the pre-configured CIP Safety can be appended to with additional I/O. I had assumed that a 'Safety' config shouldn't be messed with. Initially, I'd assumed the whole CIP-Safety Adapter option was completely separate hardware and software, because its 'Safety' stuff.

I had also hoped that a second software EIP adapter could be created in the controller using 841-1, since there are separate, available ports that could be used, BUT that is not permitted in 841-1. (I don't think that is explicitly stated in any manual, either. If trying to do so, you just hit a dead-end, but don't get any message that what you are trying to do is not even an option.)

What I needed was both the CIP-Safety comms, and separate, non-safe PLC I/O.

My actual options were (now that I've spoken to ABB engineering):

- add 840-1 (EIP FBA) to carry the non-safe PLC I/O separately

- Make the PLC use an adapter, and the robot uses its Scanner side for the PLC I/O

-- (CIP-Safety still on the robot adapter side connected to a PLC CIP Safety Scanner)

- add bytes to the adapter definition and append the PLC I/O to that.

-- (first 8 in/out bytes carry CIP Safety I/O, and must not be altered or re-mapped.)

Hopefully this clears up the question and helps others going forward.

A little more diagramming and clarity in the Application Manual for EtherNet/IP adapter/Scanner option is really required. I assume that there are different products out there that work with CIP Safety, such as a separate Safety PLC, and a PLC that has both standard I/O and a Safety controller that incorporates a CIP Safety Scanner, and if that is used with a separate master PLC for controls, you might need to separate EIP I/O and CIP Safety I/O on different ports. Adding CIP Safety networking option diagrams would help make it more explicit what the options are. (Or at least a paragraph or two explaining this issue.)

(When different contractors are responsible for different areas, their different expectations might result in a serious issue late in the process. In my case, we're just supplying the robot and it's directly-controlled equipment. The cell fencing and safety requirements were handed to a different contractor.)

- Jay0

Answers

-

Thanks, I see the option.

But, 841-1 does not allow for more than one adapter? It would be nice if the configuration tool made this more clear.

The CIP-Safety option implies that it is ADDING an adapter, not taking over the adapter of 841-1. Again, it would be nice to know at configuration time that the option will limit what we can do.

Initially, we did configure this without CIP Safety, and would have had the adapter open for PLC comms, and after we (as integrators) forwarded this to the client who wanted to order this robot themselves, the CIP Safety option was added, which took over the adapter, but I did not know that this would happen until I began to attempt to configure my PLC communications. Hard to blame anyone but ABB on this issue. There is NO indication that CIP Safety will take over the 841-1 adapter.

Post edited by Jaycephus on- Jay0 -

Digging through the Anybus EIP Adapter manual, I do find a reference to 840-1 as the option required, but ironically, the 840-1 option in the configurator does not reference the EtherNet/IP Anybus Adapter.

I still haven't found a clear statement anywhere that adding CIP-Safety takes over your EIP scanner/adapter and will require adding 840-1 in order to have a separate adapter available for PLC comms.

It's obvious now, but you wouldn't know this from anything in the configurator, or from any documentation I've found so far, including the Application manual

EtherNet/IP Scanner/Adapter manual. I guess it is implied, but I was a little surprised that the 841-1 option only gives you a single adapter connection, or that it doesn't make the CIP-safety issue more explicit.

- Jay0 -

Are you trying to create another device TYPE, or another UNIT using that type?Lee Justice0

-

Hi Lee,

As I understand it, with the options we have installed, we would either need to order 840-1 (hardware included, not just software), or not use CIP Safety (use hardwire safety to robot), or use the robot scanner to a PLC adapter.- Jay0 -

I am asking because you can have more than one unit of a given unit type. The error says too many devices. So did you try to make another internal device type, or another unit using the one type?Lee Justice0

-

That's the process I tried going through in the first post.

That error is given when trying to make another EtherNet/IP internal device, since the factory-configured CIP-Safety configuration is squatting there.

Specifically, it is limited to making one adapter device on the pre-configured EtherNetIP network.

My next thought was to make another network and build from there.

I did make another IP setting for LAN3, which is open.

But when trying to make another Industrial Network that uses LAN3, the Name field is read-only, and I cannot continue.

If using a template other than 'Default,' the name field is still read-only, and is filled with a pre-existing name, so then a second Network cannot be created due to one with that name already existing.

Thanks,- Jay0 -

Could this

or this be the issue (FBA = (Anybus) fieldbus adapter)

0

Categories

- All Categories

- 5.7K RobotStudio

- 402 UpFeed

- 21 Tutorials

- 16 RobotApps

- 307 PowerPacs

- 407 RobotStudio S4

- 1.8K Developer Tools

- 251 ScreenMaker

- 2.9K Robot Controller

- 368 IRC5

- 92 OmniCore

- 8 RCS (Realistic Controller Simulation)

- 859 RAPID Programming

- 43 AppStudio

- 4 RobotStudio AR Viewer

- 19 Wizard Easy Programming

- 111 Collaborative Robots

- 5 Job listings