Forum Migration Notice

Update (2026-01-21): The user forums are now in read-only mode pending the data migration.

Update (2026-01-12): The user forums will be put into read-only mode on the 21st of January, 00:00 CET, to prepare for the data migration.

We're transitioning to a more modern community platform by beginning of next year. Learn about the upcoming changes and what to expect.

Update (2026-01-12): The user forums will be put into read-only mode on the 21st of January, 00:00 CET, to prepare for the data migration.

We're transitioning to a more modern community platform by beginning of next year. Learn about the upcoming changes and what to expect.

IndReset after toolchange moves (virtual) axis position 1000's of degrees off

Hi,

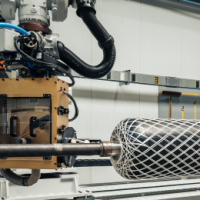

I'm comissioning a machine to have an additional tool, both have a MU100 motor but have different funcitons. One is used to rotate a payout axis for composite winding and the other is used to feed composite tapes through a set of rollers.

Both are set to be rotational axes (Indreset doesn't work with linear axes).

It's the exact same issue as discussed here one year ago: https://forums.robotstudio.com/discussion/14245/incorrect-behaviour-of-indreset-after-tool-change

I've contacted ABB but they have not replied for a number of days now.

We do have the correct option "630-1 Servo Tool Change" on the controller to facilitate this and are following correct procedures, deactivating before toolchange etc.

Does anyone know what this issue could be?

If I get an answer from ABB I'll post it here as future reference, but if anyone knows what causes this and what can be done to solve it I'd love to hear it!

Best regards,

TANIQ

I'm comissioning a machine to have an additional tool, both have a MU100 motor but have different funcitons. One is used to rotate a payout axis for composite winding and the other is used to feed composite tapes through a set of rollers.

Both are set to be rotational axes (Indreset doesn't work with linear axes).

It's the exact same issue as discussed here one year ago: https://forums.robotstudio.com/discussion/14245/incorrect-behaviour-of-indreset-after-tool-change

I've contacted ABB but they have not replied for a number of days now.

We do have the correct option "630-1 Servo Tool Change" on the controller to facilitate this and are following correct procedures, deactivating before toolchange etc.

Does anyone know what this issue could be?

If I get an answer from ABB I'll post it here as future reference, but if anyone knows what causes this and what can be done to solve it I'd love to hear it!

Best regards,

TANIQ

Engineer @ TANIQ

www.taniq.com

www.taniq.com

Tagged:

0

Answers

-

From ABB:

Option 630-1 "Servo Tool Change" and "610-1 Independent Axis" are not supported together.

To be able to calibrate a tool after a toolchange normally STCalib is used. However that RAPID instruction is used for gripper type servo tools. Which is not the case in this application.

Possible solutions might include, having a single mechanical unit for all tools and recalculate axis positions for different gear ratio's.

I will be trying a few options later this week.Engineer @ TANIQ

www.taniq.com0 -

We might have isolated the issue and may have a solution:

Lets say we have a toolaxis which has a reduction of 3.2

Meaning 3.2 motor revolutions for 1 axis revolution.

When we rotate the axis 1.8 revolutions the motor will sit at (1.8*360*3.2=2073.6 degrees)

On the measurement link it will read 5 revolutions plus 273.6 degrees.

Now when we IndReset ref\short and rotate to 0 the axis will move another 0.2 revolutions to complete the 2 revolutions.

after the reset the axis position will have moved from 648 to -72 degrees.

Axis is now at -72

motor is at 5*360 + 273.6

Rotating the other 72 degrees will move the motor to 5*360 + 273.6 + 72*3.2 = 2304.

Axis is now at 0,

motor is at 6*360 + 144 degrees.

so the new 0 position for this motor/resolver is 144 degrees different from it's original 0 position.

So Far, this will not give any issues. However, now we drop this tool (Resolver at 144) and pick up a different tool (same gear ratio) with it's resolver at 72 degrees. (only 1 axis rotation instead of 2)

Performing an IndReset now will move the axis postion a full number of 360 degree rotations, in this case 0, so no change, however the resolver still sits at 72 degrees, which devided by the gear ratio is 22.5.

Despite the tool being at the correct 0 position, the value will read +-22.5 degrees.

For this reason we think toolchange and IndReset are not supported.

Our solution (possibly):

Make sure gearbox ratio's are a full integer, so 0 on the motor's resolver will always correspond with 0 on the Axis.

Then, the gear ratio should be applied to the programmed postitions beforehand.

with for example:

Gearratio in motion config:= 3.0

in rapid:

CONS GearRatio:=3.2/3.0;

Targetpos.extax.eax_d:=Targetpos.extax.eax_d*GearRatio;

MoveL Targetpos etc. etc....;

This way programed positions would still work and the resolver will stay at 0 after each IndReset.

Granted, it's not pretty but it might just work.

We'll try in July.Engineer @ TANIQ

www.taniq.com0 -

The parameters in the MOC file are set YES for Rotating Move AND the transmission gear ratio was painstakingly, precisely set as per the guidelines ". . . the number of revolutions the motor performs for every revolution of the joint.", correct?0

-

Yes the transmission parameters are set correctly as well as rotating move.SomeTekk said:The parameters in the MOC file are set YES for Rotating Move AND the transmission gear ratio was painstakingly, precisely set as per the guidelines ". . . the number of revolutions the motor performs for every revolution of the joint.", correct?Engineer @ TANIQ

www.taniq.com0

Categories

- All Categories

- 5.7K RobotStudio

- 402 UpFeed

- 21 Tutorials

- 16 RobotApps

- 307 PowerPacs

- 407 RobotStudio S4

- 1.8K Developer Tools

- 251 ScreenMaker

- 2.9K Robot Controller

- 368 IRC5

- 92 OmniCore

- 8 RCS (Realistic Controller Simulation)

- 859 RAPID Programming

- 43 AppStudio

- 4 RobotStudio AR Viewer

- 19 Wizard Easy Programming

- 111 Collaborative Robots

- 5 Job listings